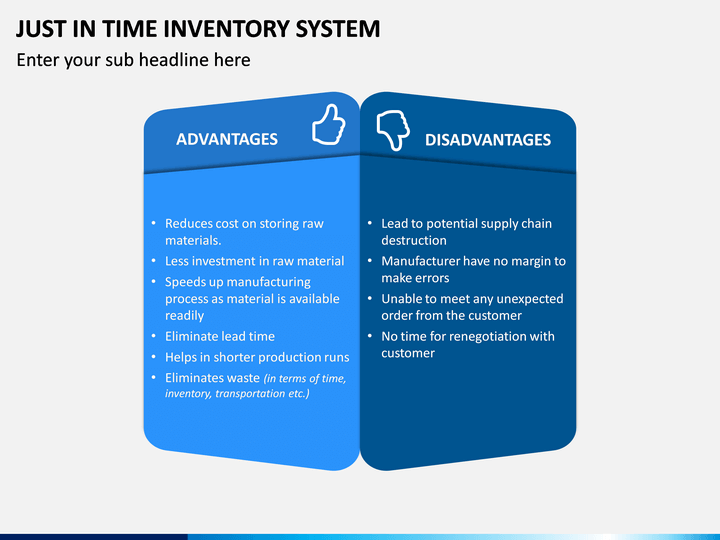

In knowledge work, the “just-in-time” concept can be applied in the same way as in manufacturing – a work item has to be in progress only if there is a demand for it. Such an imbalance can create unexpected financial gaps.

When applying a push strategy, a company’s production is based on anticipated demand, which can fail to correspond with the actual demand. Just-in-time is a production model where deliverables are produced to meet actual demands and avoid overstocking and push strategies. As a result, you’ll be able to optimize your resources and reduce the possibility of overstocking.įurthermore, applying a pull system will allow you to deliver work "just-in-time". By doing so, your company can focus on eliminating waste activities in the production process. The purpose of implementing a pull system is to build products based on actual demand and not on forecasts. A lean pull system aims to create a workflow where work is pulled only if there is a demand for it. Pull systems are part of the Lean manufacturing principles, born in the late 1940s. This allows you to minimize overhead and optimize storage costs.Įxample of how a pull system works Why Is Pull Better than Push?

Applying a pull system allows you to start new work only when there is a demand for it. What Is a Pull System?Ī pull system is a Lean technique for reducing waste in production processes. In other words, a pull system lets you consume only when you have a demand at the right time.Īside from your trip to the subway, let’s explore more about pull systems and their application. In doing so, you are already a part of a pull system based on a certain signal. Sure, you will go to the ticket machine and refill the card. Imagine, you are on the way to a subway station and trying to pass the turnstile, you notice your travel card is empty.

#A just in time inventory system usually reduces costs for update#

Integrate with external systems to get the most out of your Kanban softwareĬreate and update cards via email and reply to emails by adding a comment Reduce multitasking, alleviate bottlenecks, and keep a steady flow of work Visualize and track cross-team dependencies via card linksĬustomize your work items as needed and enhance communicationĬreate probabilistic plans for future project deliveryĪutomate your process to trigger actions when certain events occurĪnalyze your workflow’s performance through a variety of Lean/Agile charts Visualize your past, current, and future initiatives or projectsĭisplay critical business metrics and gather reports in one place Keep track of tasks and get accurate status reports in real-timeĬreate a network of interlinked Kanban boards on a team and management level Keep your teams' work in a single place with multi-layered Kanban boards Monitor business objectives, understand risks, and track the most important performance metrics Implement OKRs and align your strategy with day-to-day executionĭistribute and track work across the entire organization

0 kommentar(er)

0 kommentar(er)